New features introduced with release X8

X8

Updates:

- November 2024: released the new release X8: download list of new features introduced >

CAD Environment

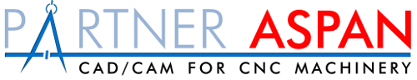

- New command "Modify > Rotate > 3 Points":

New working mode for "Rotate ” command that is added to the existing one. Unlike the canonical rotation mode used until the previous version in which it is the user who specifies the rotation angle, with this new command the angle is calculated automatically. In fact, it is possible to make the rotation by selecting 3 points:

center of rotation (p1), reference point (p2), target point (p3), as shown in the following figure.

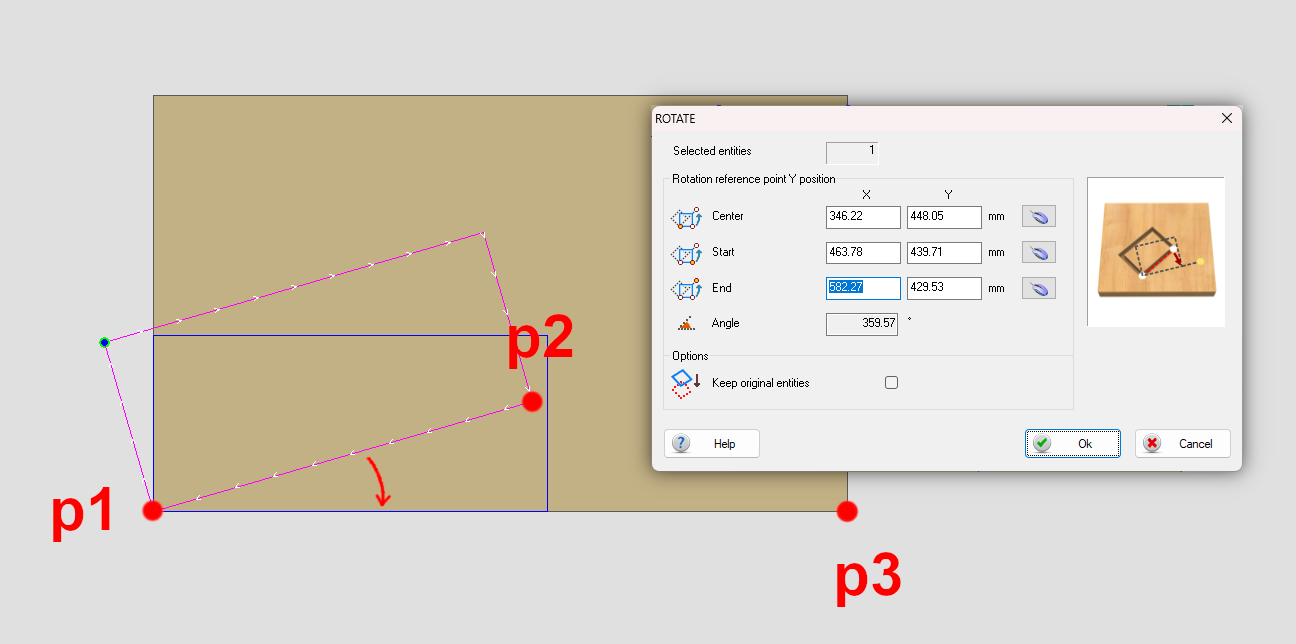

- New command "Modify > Scale > XY > 3 Points":

new mode for the "Scale" command that is added to the existing one. Unlike the canonical scale mode used up to the previous version in which the user specifies the scale factor, with this new command the scale factor is calculated automatically based on the distance of the selected points.

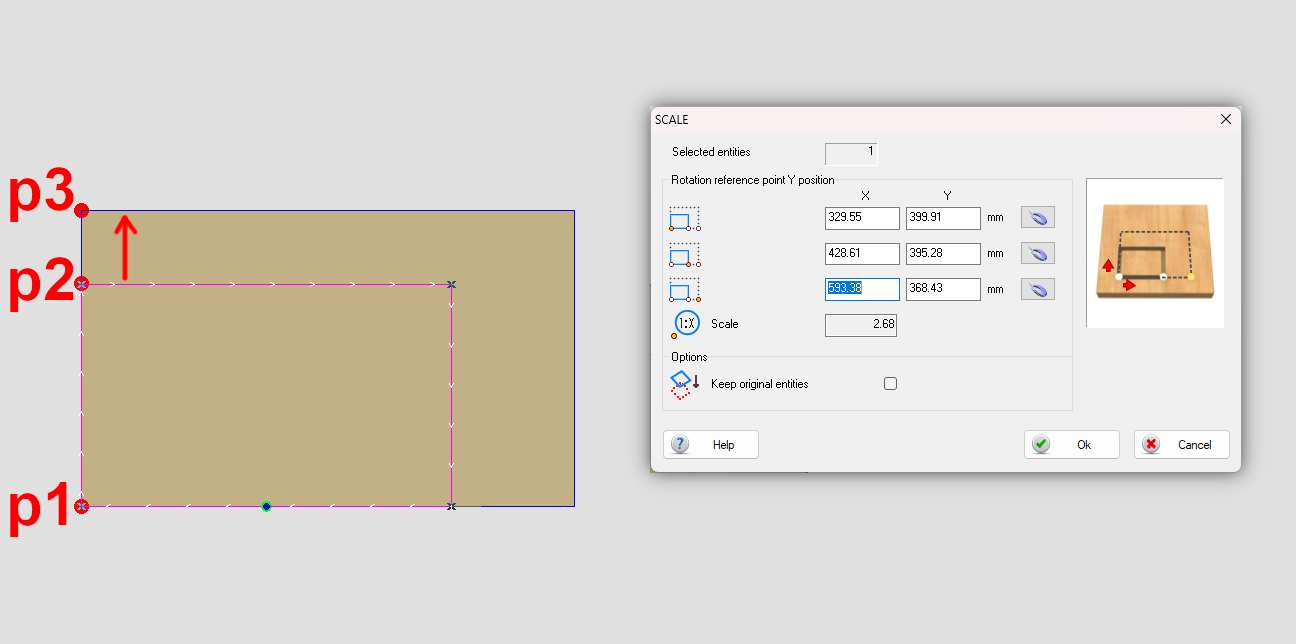

- New command "Modify > Panel > Rectangle":

you can now resize the panel by drawing the rectangle that defines its size in the desired position.

- New command "File > Save selection (Ctrl + Alt + S)":

command allows you to select part of the current drawing and save it directly as a new drawing, specifying its name and save path. - Introduced new modes for command "Path > Autojoin":

Autojoin > All shapes

Autojoin > Current face

Autojoin > Current layer

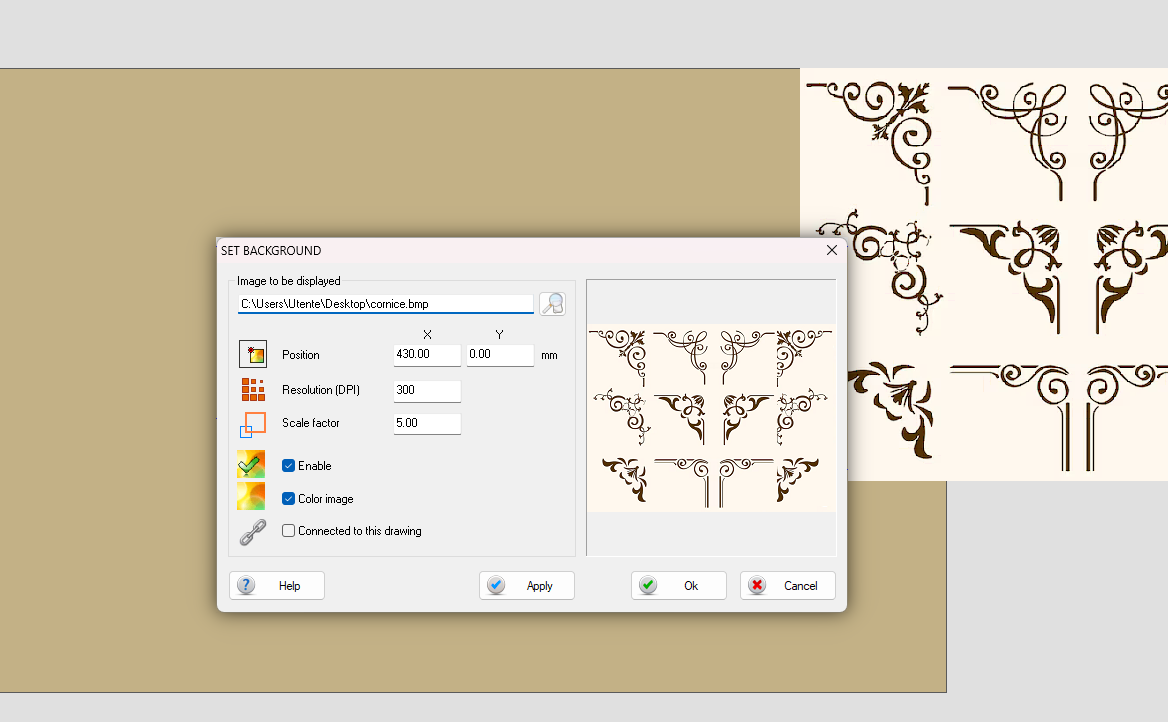

Autojoin > Selection - "Tools > Background image":

In the background image selection dialog, the [Apply] button has been added, which allows you to immediately view the image on the panel without exiting the configuration dialog. This allows the size and position of the image to be adjusted without having to enter and exit the configuration dialog several times.

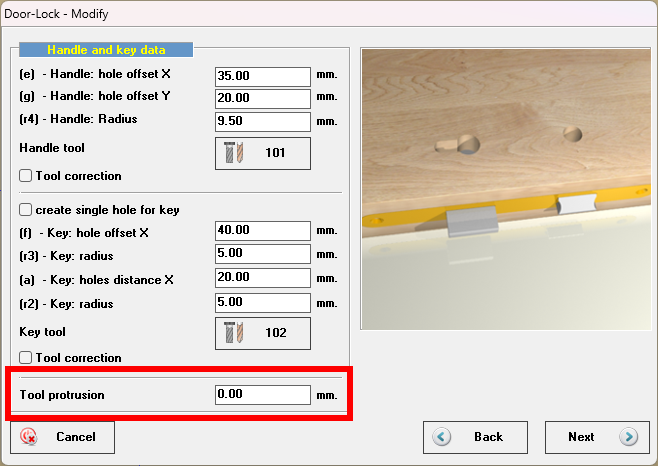

- "Draw > Hardware > Doorlock":

it is now possible to specify how far the handle machining should go down beyond the thickness of the panel.

DXF import

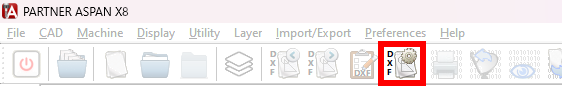

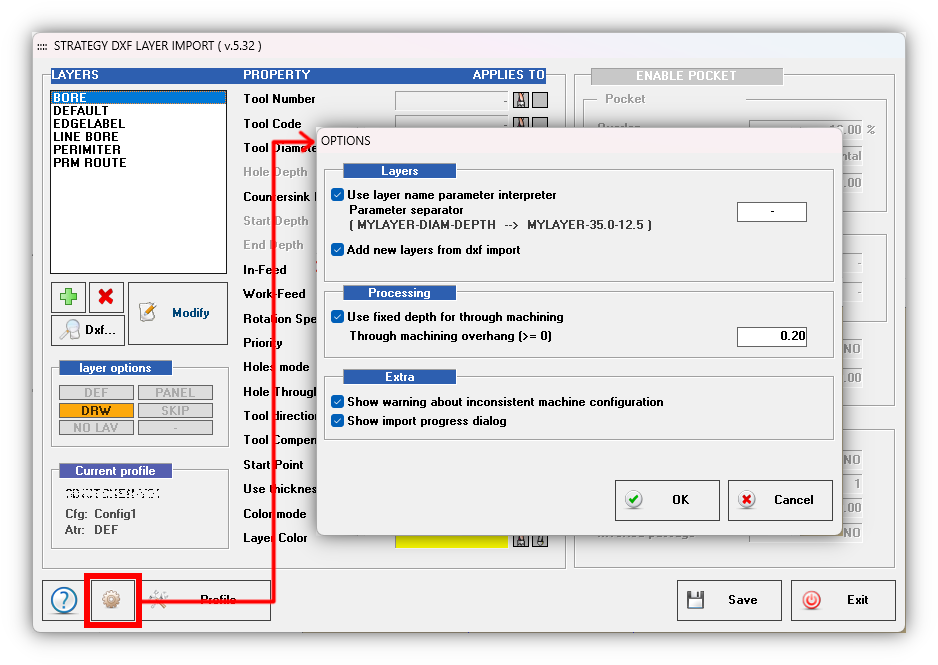

- (Supervisor) "Import Export > Configure Processor":

It is now possible to directly access the configuration dialog of the DXF import processor in use (e.g., Strategy_layer_import.pcs) without going through the import options dialog. A shortcut in the toolbar of the Supervisor environment has also been added.

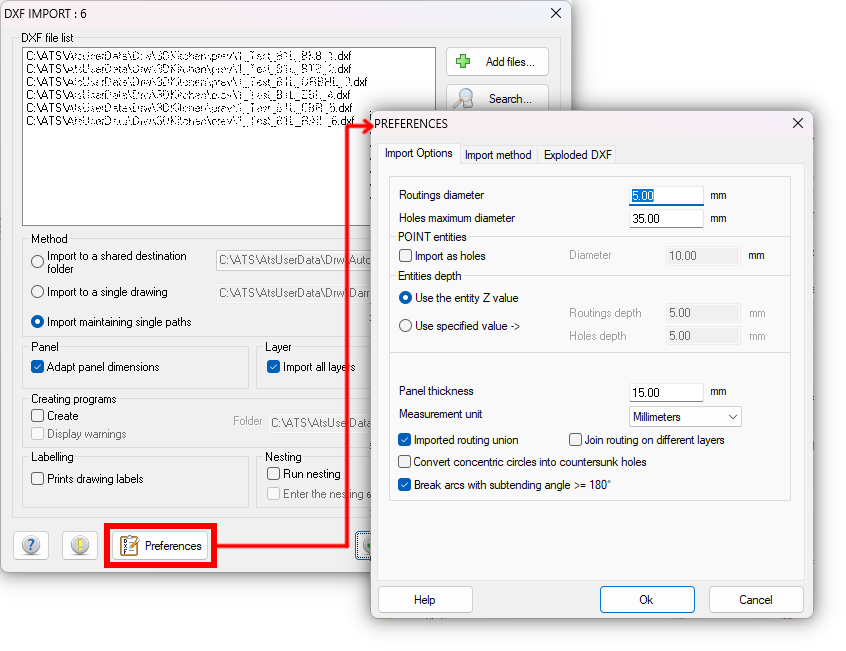

- (Supervisor) ""Import Export > Import DXF"":

It is now possible to access DXF import configuration options directly from the import dialog.

- (Nesting) "Add > Import DXF > Modify preferences" e

(Nesting) "Add > Import DXF > Configure processor":

DXF import configuration options and the selected import processor are now accessible directly from the Nesting environment either via menu command or toolbar.

DXF import processor: Strategy_layer_import.pcs

- New process options dialog:

Added new dialog to setup additional processing options.

- Option: "Use layer name parameters interpreter":

by enabling this option, the processor will search for machining parameters written in the processor name. The name will be interpreted with the following convention:

LayerName-DIAM-DEPTH

Example:

PRM ROUTE-8.1-8.6

(entities imported will have a tool diameter of 8.1mm and a depth of 8.6mm)

When this option is enabled, it is sufficient to add the name of the layer without parameters to the list of layers to interpret all its variants.

Example:

Name to be added to the layer list:

PRM ROUTE

Layers in the DXF files, recognised and interpreted during import:

PRM ROUTE-8.1-8.6

PRM ROUTE-8.1-5.5

PRM ROUTE-10.0-8.0

PRM ROUTE-8.0-5.0

etc.

NOTE: Parameters written on layer name have priority among those specified in the layer configuration dialog. If layer name doesn’t contain parameters it will be processed using settings specified in layer configuration dialog. - Option: "Add new layers from dxf import":

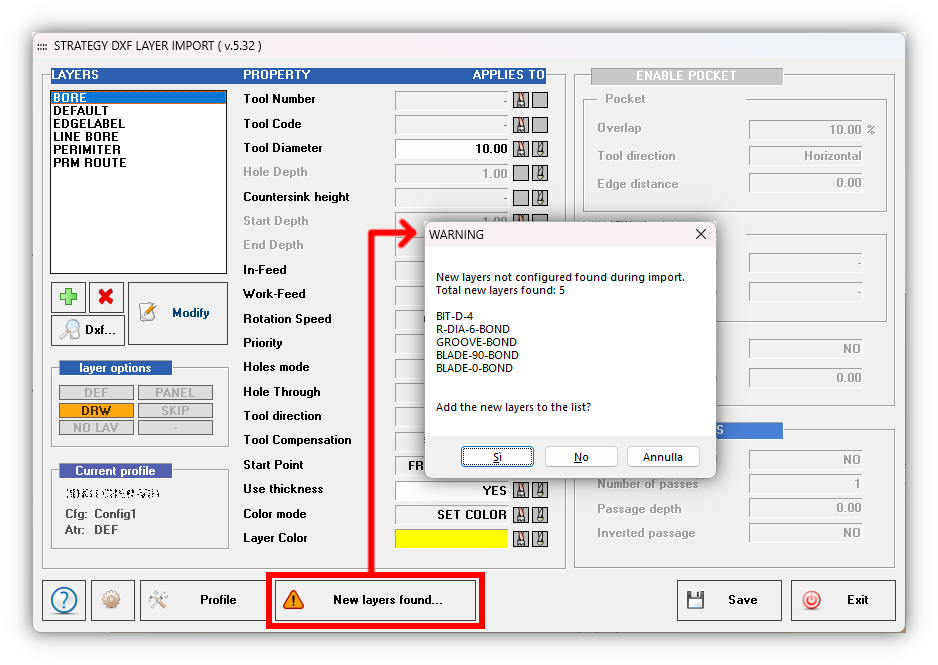

During the import of one or more DXF files, the processor detects the presence of new, unconfigured layers and notifies the user. When opening the configuration mask of the processor, a button is displayed that allows the new layers detected during the import to be added to the list. Once added to the list, it will be possible to configure their parameters using the usual procedure.

- Option: "Use fixed depth for through machining":

For all machining operations with a depth equal to or greater than the thickness of the panel, a fixed bore depth is set according to the ‘Through machining projection’ parameter. ‘Through machining projection’ must be a positive value equal or greater than 0.

Example:

Through machining projection = 0.20

Panel thickness = 18.00

Machining depth will be 18.20. - Option: "Show warning about inconsistent machine configuration":

The processor notifies if the layer configuration has been created for a different machine configuration than the one currently in use. - Option: "Show import progress dialog":

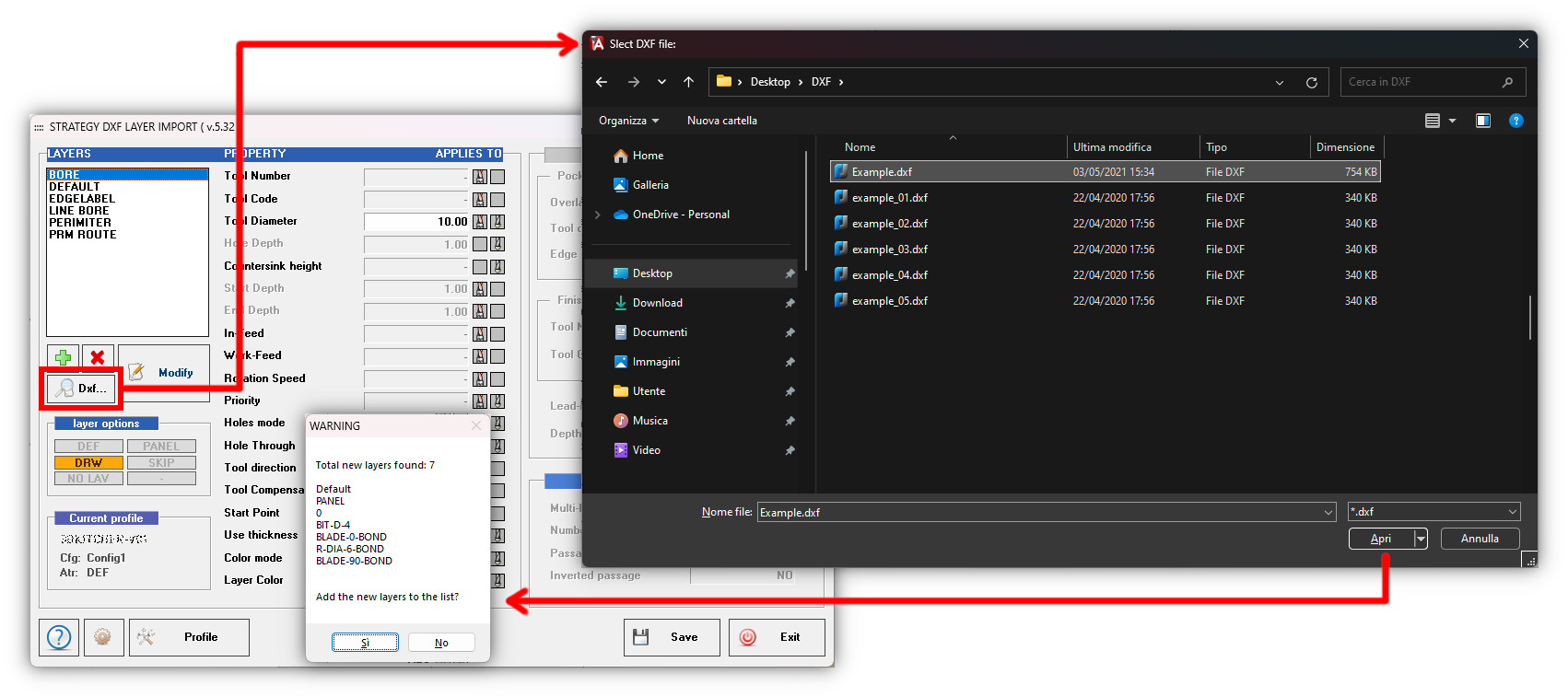

Show/Hide the import progress dialog. - "Add new layer from DXF":

It is now possible to add to the list of layers, those present in a specified DXF file.

Once the detected layers have been added to the layer list, it is necessary to proceed with their configuration by selecting a new layer name and clicking the [ Modify ] button.

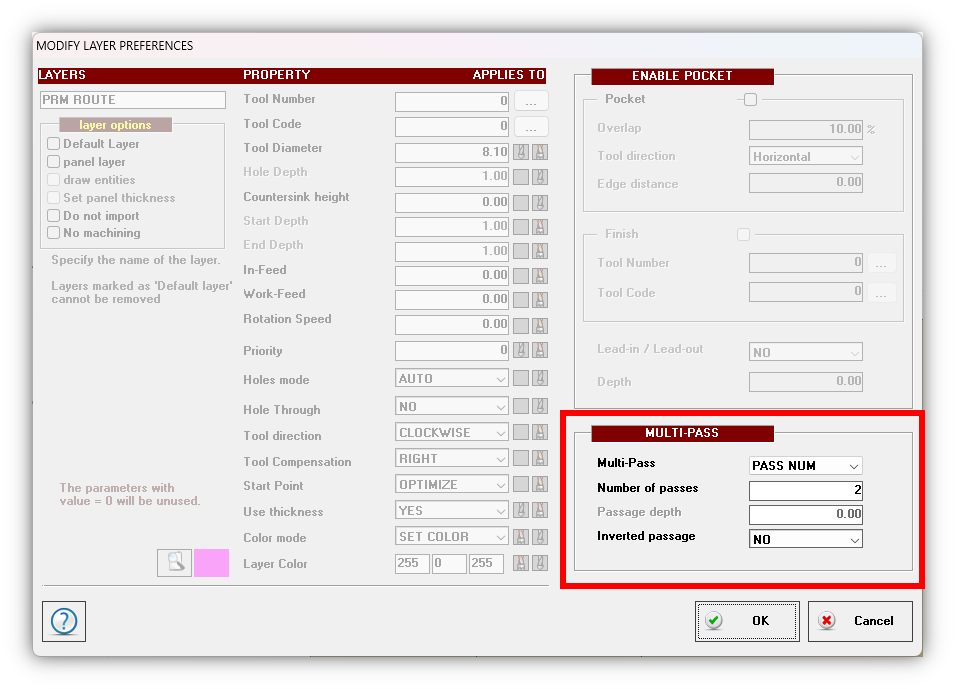

Once the detected layers have been added to the layer list, it is necessary to proceed with their configuration by selecting a new layer name and clicking the [ Modify ] button. - "Multipass machining":

It is now possible to define multi-pass machining by specifying the number of passes to be made or the machining depth of each pass made.

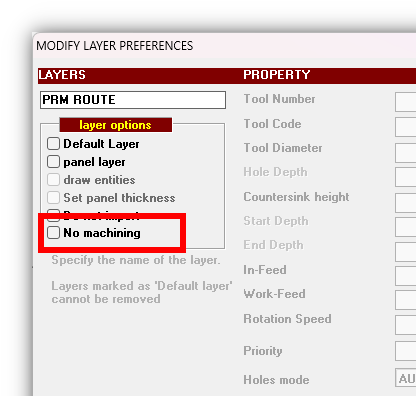

- "Non-machinable layer":

By activating the “No machining” option, you can set a layer as “non-machinable”. For the selected layer all geometries will be imported but no tools will be assigned.

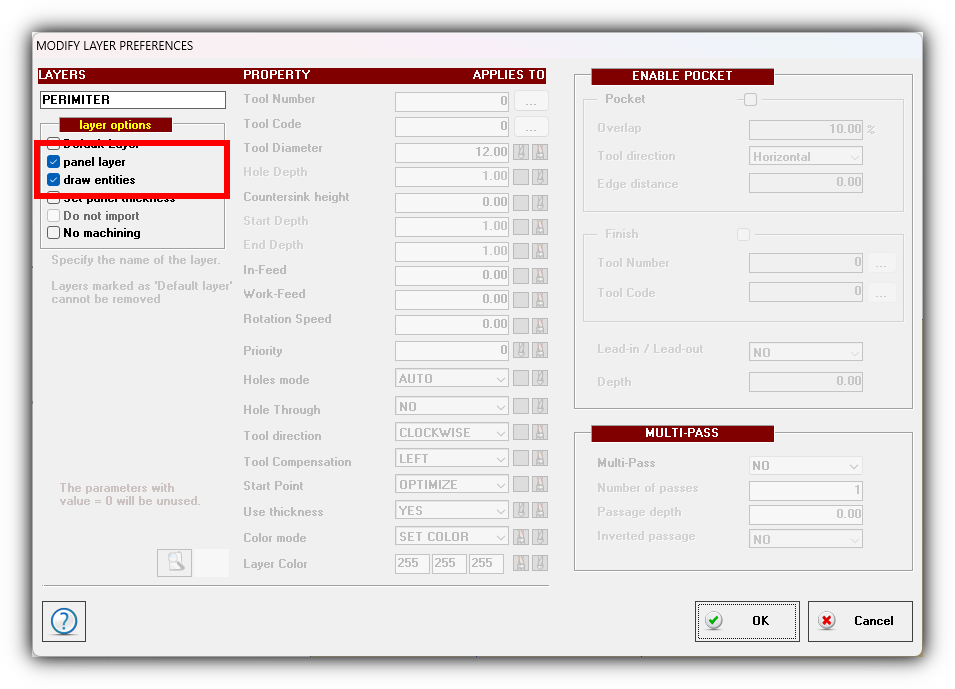

- "Improved panel size recognition":

Improved panel size recognition for DXF files where layer “PANEL” is not explicitly defined. Panel size is calculated starting from panel contour machining layer configured in “Strategy_Layer_import” setup. Panel contour layer must contain a closed form of any shape.

Example:

Layer that contains the contour routing (e.g. PERIMETER).

Enable the option "Panel layer" and the option "Draw entities".

Complete the configuration setting up all machining properties for perimeter cut-out routing.

In order to properly import DXF files configured as above and for which the “PANEL” layer is therefore not defined, it is necessary to disable the “Adapt panel dimensions” option from the import dialog.

Other improvements

- Added support for new CNC machines.